Home > Battery Production Line

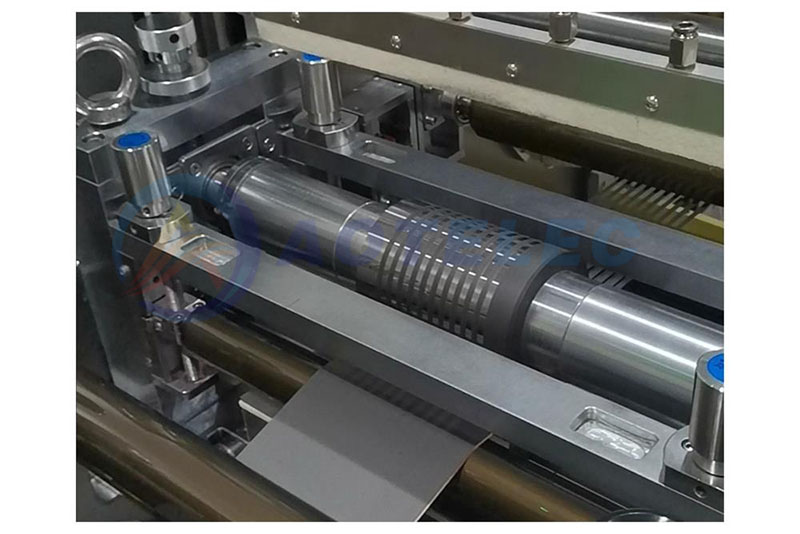

This equipment is used for the slitting process of lithium battery electrode coil, mainly suitable for cutting multiple narrow strips. The equipment has high cutting accuracy, adopts closed-loop tension control, and has a stable cutting structure. After cutting, the pole pieces have no defects such as ruffles, burrs, indentations, etc. Designed for the micro-batteries, typically, the Bluetooth batteries.

Functional Features:

1.The overall cantilever design of the equipment facilitates the retrieval, placement, threading, and maintenance of materials;

2.Closed loop control of unwinding tension, measurement of roll diameter, ensuring stable feeding, and early warning of material shortage;

3.The cutting blade holder is independently designed for easy maintenance and switching;

4.The cleaning structure design of the slitting knife facilitates blade maintenance and ensures slitting quality;

5.Four station winding to improve production efficiency;

6.Dust removal treatment at multiple stations before and after slitting to ensure the quality of the polarizer;

7.Low tension design for winding, ensuring stable slitting of narrow pole pieces;

8.The design of the winding traceability mechanism ensures the stability of slitting and winding.

Specification:

Product Name | Battery Electrodes Slitting Machine |

Working Voltage | 380V AC, Three-phase, 50/60 Hz |

Cutting Speed | 0-40m/min |

Automatic Tension control | 0-100N,+/-2N |

Maximum Reeling Diameter | 350 mm |

Maximum Unreeling Diameter: | 450 mm |

Automatic unwinding correction | accuracy ± 0.5mm |

Each electrode strip range | 3 - 10 mm width |

Total cutting width | 300 mm |

After cutting | there are no ruffles, no indentations, no knife overprints, and no burrs on the appearance |

Weight | 2.5T |

Contact: Lika

Phone: +86-19906035385

Tel: 0086-592-7161550

Email: sales@aotbattery.com

Add: No.168, Zhaogang Road, Xiamen City, China