Home > Battery Pack Assembly Line

AOT-AFA-DE200 multifunctional coating machine, roll to roll method, continuous and intermittent coating, width 200mm, coating width 50-160mm, modular head structure, optional extrusion coating, transfer coating, scraper coating, micro gravure coating, extrusion transfer coating, extrusion scraper coating. When multifunctional coating, the coating function can be switched by changing the substrate threading scheme. Optional extrusion coating die head, optional corona treatment, static elimination, substrate flattening, NMP treatment, feeding device, infrared drying, ultraviolet curing, drying oven quantity, etc.

Series products can be equipped with coating methods, drying methods, and functional modules according to needs. This machine is equipped with extrusion coating and transfer coating functions;

Switching the coating function by changing the winding method is convenient to operate;

Extrusion coating:

1. Slot die extrusion coating, with high coating accuracy and good consistency;

2. Multiple coating die heads can be configured to adapt to different coating parameters;

3. Sealed operation of slurry without external parameter interference;

4. Continuous coating and stripe coating can be achieved by configuring different gaskets;

5. Configure the slurry feeding device MSK-156.

Transfer coating:

1. Wide coating window, suitable for various coating scenarios, especially suitable for the early research and development stage;

2. Can achieve continuous and intermittent coating;

3. Measurement with comma scraper, manual adjustment of scraper height, high coating accuracy;

4. Manually adjust the coating width;

Substrate tension control, stable tape running;

PLC control, HMI operation, convenient and easy to use;

Small size, easy to operate;

Configure a hot air drying oven with single-sided air outlet for high-quality drying effect.

Technical Parameter

Power Supply | Single phase AC220V ± 10%, frequency 50Hz, power approximately 3.55KW | |

Gas Source | 0.5-0.8MPa compressed air | |

Width of Guide Roller | 200mm | |

Substrate Width | Max.180mm | |

Mechanical Speed | 0.01-1.0m/min | |

Extrusion Coating | Coating Type | Continuous coating |

Coating Speed | Max.0.2m/min (reference graphite negative electrode coating speed, viscosity 2000 mPa. s, solid content 45%, coating dry thickness 90u m) | |

Coating Width | 50-160mm (replace gasket) | |

Coating Die Brand | Domestic | |

Gasket | Comes with 1 set of gaskets as standard, with opening size specified by the customer | |

Coated Steel Rod | Ф80mm, Surface chrome plating, circular runout ≤ 3 μ m (measured by mechanical micrometer) | |

Mold Head Movement | Manual adjustment | |

Transfer Coating

| Coating Type | Continuous coating, intermittent coating |

Coating Speed | Max.0.2m/min (reference graphite negative electrode coating speed, viscosity 2000 mPa. s, solid content 45%, coating dry thickness 90 u m) | |

Coating Width | 50-160mm (adjustable through baffle) | |

Coated Steel Rod | Ф80mm, Surface chrome plating | |

Coating Roller | Ф80mm, Surface EPDM rubber | |

Rubber Roller Movement | Cylinder Driven | |

Coating Scraper | Ф50mm Surface chrome plating, double-edged | |

Scraper Adjustment | Manual adjustment | |

Coating Length | Coating length 10-5000mm, blank length 10-500mm | |

Two sided alignment | ± 0.5mm (length direction) | |

Hot Air Drying | Drying box | Single section length 0.5m, total 1 section |

Heating method | Electric heating, power 2.4KW | |

Drying temperature | Max 130 ℃ | |

Exhaust air | Centrifugal fan, air volume 570m ³/h, interface: 5-inch Aluminum Foil duct. | |

Guide Roller | Aluminum alloy, surface hard oxidation, diameter of Ø 50mm | |

Roll Diameter | Max.Ф250mm | |

Retracting and Unwinding Core | 3-inch expansion shaft | |

Operation Direction | Along the direction of foil transfer, the right side is the operating side | |

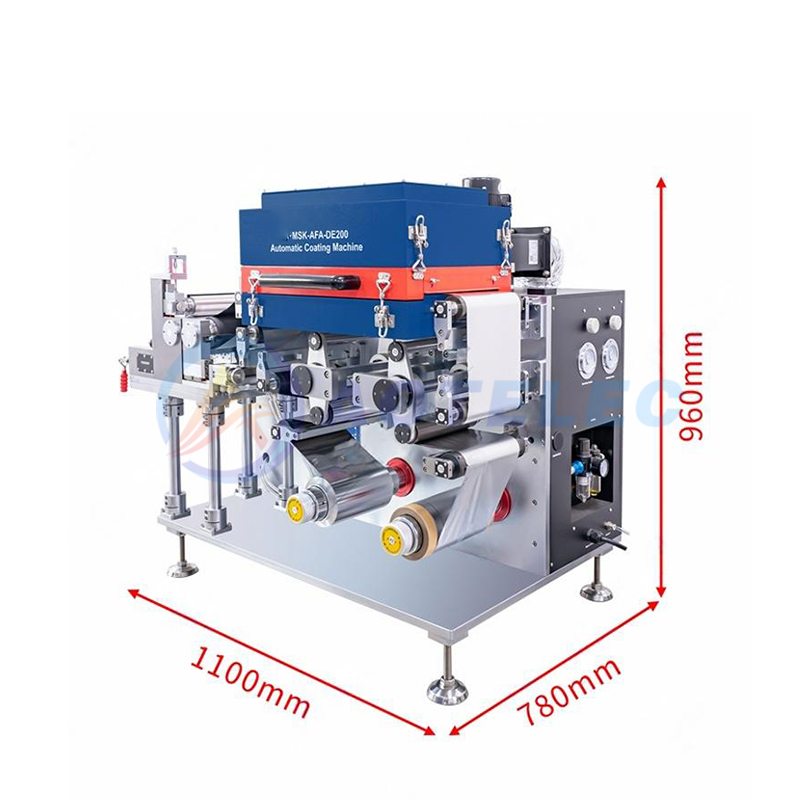

Coating Machine Size | L1200 * W780 * H960mm | |

MSK-156 Feeding Machine Size | L780 * W230 * H810mm | |

Weight Coating Machine | 560Kg | |

MSK-156 Feeding Machine Weight | 58Kg | |

Contact: Lika

Phone: +86-19906035385

Tel: 0086-592-7161550

Email: sales@aotbattery.com

Add: No.168, Zhaogang Road, Xiamen City, China