How far are high energy density lithium-sulfur batteries from commercial applications?

How far are high energy density lithium-sulfur batteries from commercial applications?

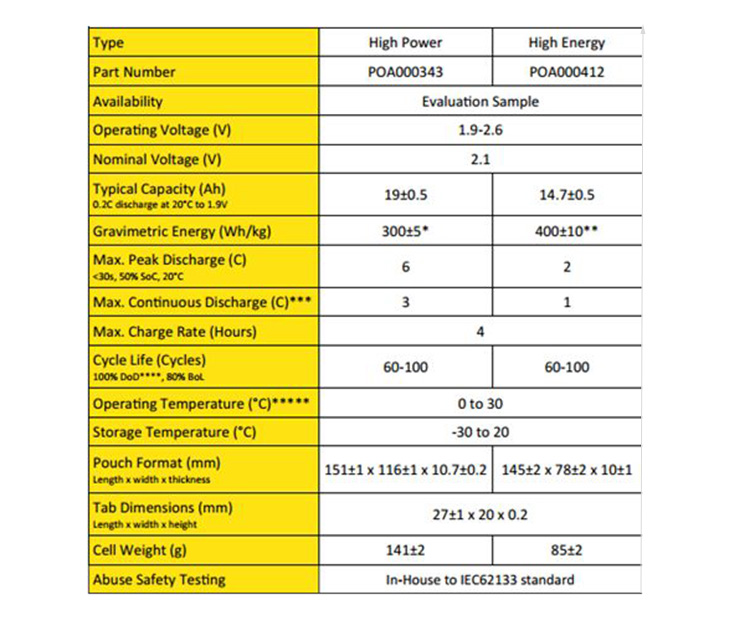

British OXIS company is one of the foreign companies focusing on the research and development of lithium-sulfur batteries. According to reports, OXIS has developed a high-energy density lithium-sulfur soft pack battery with a nominal voltage of 2.1 V and a typical capacity of 14.7 Ah. At a discharge rate of 0.1C, the mass energy density reaches 400 Wh/kg, the volume energy density is 300 Wh/L, and the cycleability reaches 60-100 cycles.

The product is planned to be mass-produced at manufacturing plants in Brazil and the United Kingdom. At the same time, the company recently reported the test results of the new lithium-sulfur prototype battery, the energy density reached 471 Wh/kg, the company announced to increase to 500 Wh/kg in the next year, and plans to work with customers and partners to develop The development target for lithium-sulfur batteries with solid battery electrolytes is set at 600 Wh/kg.

Research scientists at OXIS believe that they have the ability to expand the weight and volumetric energy density to 600 Wh/kg and 800 Wh/L, and can significantly extend the life cycle. For ultra-high energy density lithium-sulfur batteries, OXIS will now be upgraded to TRL4 in 2021 based on the technology maturity TRL2. Please note that the TRL for mass production is 9.

The company will develop two types of batteries (20 Ah, 2.1 V, high weight energy density, low temperature tolerance) to meet the specific requirements of the future aerospace and automotive fields:

1. High energy density batteries (> 500 Wh/kg) for small electric aircraft (2 seats), drones and high altitude pseudolites (HAPS).

2. High energy density and high power density batteries for automotive and electric vertical take-off and landing (eVTOL) aircraft applications (> 400 Wh/kg, power density parameters not given).

The product is planned to be mass-produced at manufacturing plants in Brazil and the United Kingdom. At the same time, the company recently reported the test results of the new lithium-sulfur prototype battery, the energy density reached 471 Wh/kg, the company announced to increase to 500 Wh/kg in the next year, and plans to work with customers and partners to develop The development target for lithium-sulfur batteries with solid battery electrolytes is set at 600 Wh/kg.

Research scientists at OXIS believe that they have the ability to expand the weight and volumetric energy density to 600 Wh/kg and 800 Wh/L, and can significantly extend the life cycle. For ultra-high energy density lithium-sulfur batteries, OXIS will now be upgraded to TRL4 in 2021 based on the technology maturity TRL2. Please note that the TRL for mass production is 9.

The company will develop two types of batteries (20 Ah, 2.1 V, high weight energy density, low temperature tolerance) to meet the specific requirements of the future aerospace and automotive fields:

1. High energy density batteries (> 500 Wh/kg) for small electric aircraft (2 seats), drones and high altitude pseudolites (HAPS).

2. High energy density and high power density batteries for automotive and electric vertical take-off and landing (eVTOL) aircraft applications (> 400 Wh/kg, power density parameters not given).