Home > News

A sealing machine for batteries is a piece of used in the manufacturing process of batteries to create a reliable and secure seal. The sealing process is a critical step in battery production, especially for rechargeable lithium-ion batteries, as it prevents leakage of electrolyte, ingress of contaminants, and ensures the overall safety and performance of the battery.

There are several types of sealing machines used for different battery formats and production scales. Here are a few common types:

1. Heat Sealing Machine:

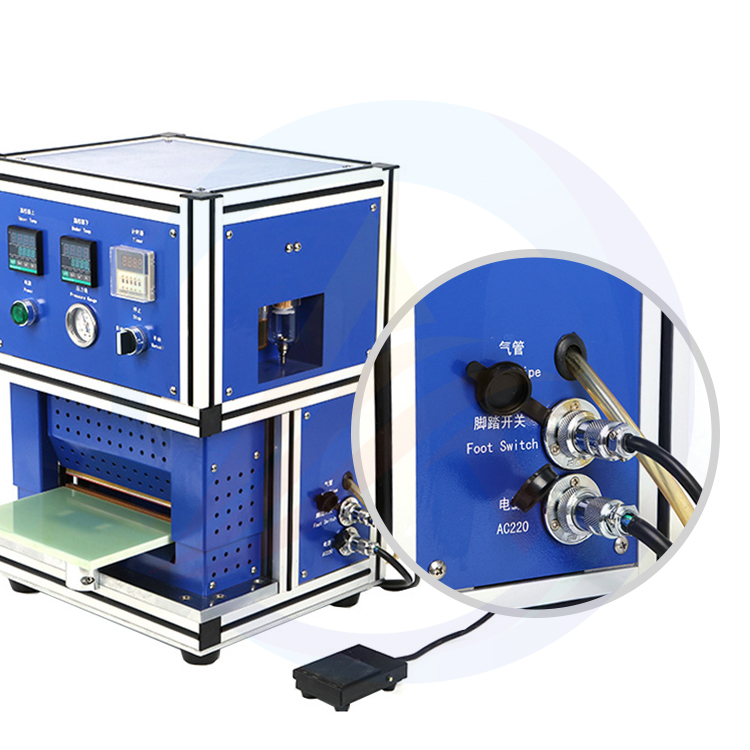

This type of machine uses heat to seal the battery cell. It typically consists of a heating element or a heated die that is pressed onto the battery's sealing area. The heat melts or activates a sealant material, such as a polymer, which forms a tight and durable seal when cooled.

2. Ultrasonic Sealing Machine:

Ultrasonic sealing machines utilize high-frequency vibrations to generate localized heat and pressure, which fuses the sealing components together. This method is suitable for batteries with ultrasonic-activated sealants or plastic components.

3. Induction Sealing Machine:

Induction sealing machines use electromagnetic induction to heat a metallic foil or liner placed on the battery cell's sealing area. The heat created by the induced current melts a thermoplastic layer, establishing an airtight seal upon cooling.

4. Laser Sealing Machine:

Laser sealing machines employ laser technology to melt or weld the sealing materials. A laser beam focused on the battery's sealant area generates localized heat, allowing the sealing components to fuse together and create a hermetic seal.

The sealing machine for batteries is mainly used in battery manufacturing plants or battery assembly facilities. These machines are specifically designed to seal the battery container, ensuring that the contents inside, such as the electrolyte and electrode materials, remain securely enclosed.

The sealing process is a critical step in battery production as it prevents leakage or contamination of the battery, maintains the integrity of the internal components, and ensures the safety and performance of the battery. The sealing machine typically employs various techniques such as heat sealing, ultrasonic welding, or crimping to create a tight and reliable seal.

Battery sealing machines are commonly used in the production of various types of batteries, including lithium-ion batteries, nickel-metal hydride (NiMH) batteries, lead-acid batteries, and other types of rechargeable or non-rechargeable batteries. They are essential equipment in the battery manufacturing industry to achieve efficient and reliable battery sealing.

Contact: Lika

Phone: +86-19906035385

Tel: 0086-592-7161550

Email: sales@aotbattery.com

Add: No.168, Zhaogang Road, Xiamen City, China