Home > Battery Pack Assembly Line

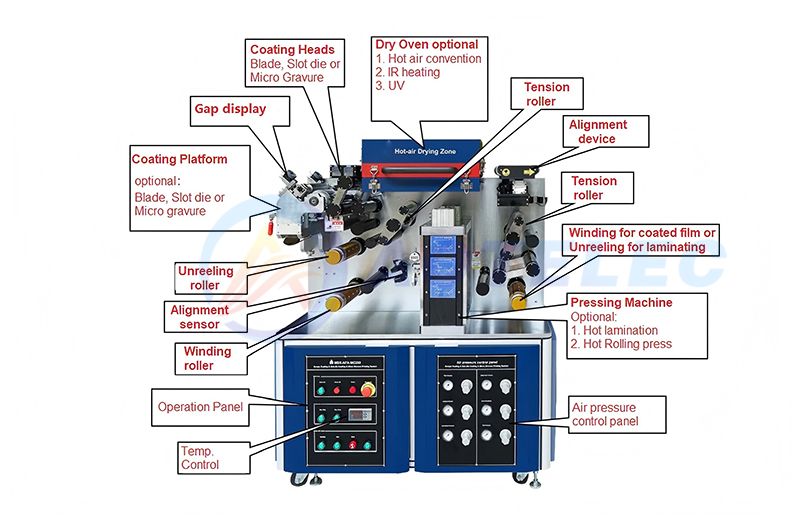

This device has multiple coating methods and coating processing functions to meet different process requirements.

It mainly integrates three coating methods: scraper coating, extrusion coating, and micro gravure coating, which can achieve various coating processes such as continuous coating, stripe coating, and ultra-thin coating coating.

There are also processes for substrate corona treatment before coating, coating rolling after coating, and film coating. Mainly used in the coating process of positive and negative electrode sheets for lithium batteries, it is also applicable to the coating process of some other types of slurries and substrates.

Functional Features

Multiple coating functions are available for easy switching.

Multiple drying methods are available, modular structure, and easy replacement.

Optional substrate corona function.

Optional cold/hot rolling function.

Optional cold/hot film coating function.

Closed loop tension control of substrate, stable running, and low tension running can be achieved.

PLC control, HMI operation, convenient and easy to use.

The device has a small size and is suitable for use in laboratories.

Standard MSK-50 sampler for fast online sampling and measurement.

Technical Parameter:

Product Name | Versatile R2R Coating Machine | |

Power Supply | Voltage single-phase AC220V ± 10% (customizable 110VAC), frequency 50Hz/60Hz, power 7KW | |

Air Source | 0.5-0.8MPa compressed air | |

Width of Guide Roller | 200mm | |

Substrate Width | Max.180mm | |

Mechanical Speed | Max.5m/min | |

Doctor Blade Coating | Coating Type | Continuous coating |

Coating Width | 50-150mm, adjustable through baffle | |

Coating Thickness | 30-200 μ m (depending on the slurry) | |

Accuracy | ≤± 3 μ m (excluding edge abnormal areas, sampling and measurement standards refer to product evaluation)

| |

Surface Density | ≤± 1.5% (including substrate, excluding edge abnormal areas, sampling and measurement standards refer to product evaluation)

| |

Box Capacity | About 0.5L (coating width 150mm)

| |

Scraper Diameter | Ф50mm | |

Back Roller Diameter | Ф100mm | |

Slot Die coating | Coating Type | Continuous coating, stripe coating |

Coating Width | 50~160mm,Replace gasket adjustment | |

Coating Thickness | Standard mold head, single-sided thickness of 15-50 μ m (depending on the slurry) | |

Accuracy | ≤ ± 2 μ m (excluding edge abnormal areas, sampling and measurement standards refer to product evaluation) | |

Surface Density | ≤± 1.5% (including substrate, excluding edge abnormal areas, sampling and measurement standards refer to product evaluation) | |

Mold Cavity Volume | Approximately 8ml | |

Back Roller Diameter | Ф100mm | |

Micro-Gravure Coating | Coating Type | Continuous coating |

Coating Width | 50-180mm, adjust by replacing the gravure roller | |

Coating Thickness | Accuracy ≤ ± 1.5 μ m (excluding edge abnormal areas, sampling and measurement standards refer to product evaluation) | |

Box Capacity | Approximately 0.2L | |

Gravure Roller Diameter | Ф30mm | |

Hot Air Drying

| Method | Electric heating, hot air direct discharge |

Airflow | Max.3.3/2840(Cm³/RPM), Wind valve regulation | |

Temperature | Max 150 ± 5 ℃, adjustable | |

Power | 3KW, Standard 1KW finned heating tube | |

Length | 500mm | |

infrared drying

| Method | Infrared heating tube |

Airflow | Max.3.3/2840 (CMM/RPM), air valve adjustment | |

Temperature | Max 150 ± 5 ℃, adjustable | |

Power | 3x0.7KW, adjustable | |

Length | 500mm | |

UV Curing

| Method | UV curing lamp tube |

Airflow | Max.3.3/2840(CMM/RPM), Wind valve regulation | |

UV lamp | Power and wavelength can be designed according to requirements | |

Length | 500mm | |

Roll Rolling | Method | Cold rolling or hot rolling |

Roll Size | Φ150x200mm, Circular runout better than ± 2 μ m (at room temperature), surface hardness ≥ HRC60, roughness Ra ≤ 0.4 | |

Heating Roller | Max 100 ℃, accuracy ± 3 ℃ (optional function) | |

Rolling Gap | 0.5~2mm | |

Composite Film Coating | Method | Cold pressing or hot pressing |

Steel Rod | Φ150x200mm, Circular runout better than ± 2 μ m (at room temperature) | |

Rubber Roller | Φ150x200mm, Fine grinding of roller surface | |

Heating Roller | Max 100 ℃, accuracy ± 3 ℃ (optional function) | |

Pressure | Max.1200N, Cylinder pressurization, precision adjustable | |

Intermittent | Manually adjusted, with a dial gauge display accuracy of 0.01mm | |

Tension Control | 5-40N | |

Corona Treatment | 2 ceramic electrodes with a power of approximately Max.2KW | |

Rolling Accuracy | ± 0.5mm | |

Roll Diameter | Max.250mm | |

Equipment Size | L1260mm*W850mm*H1600mm | |

Weight | 1T | |

Contact: Lika

Phone: +86-19906035385

Tel: 0086-592-7161550

Email: sales@aotbattery.com

Add: No.168, Zhaogang Road, Xiamen City, China