Home > Battery Pack Assembly Line

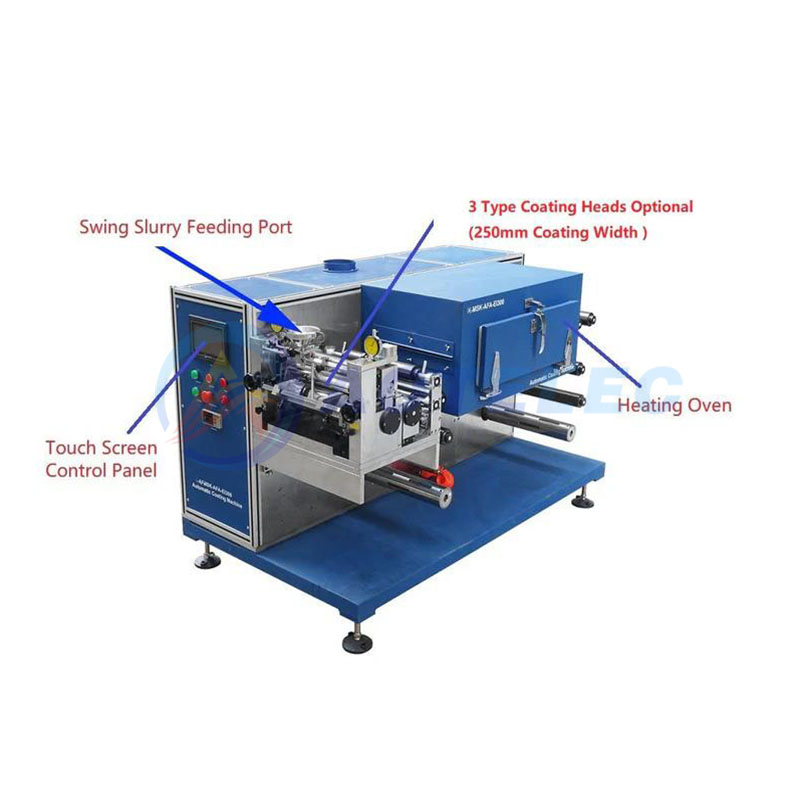

AOT-AFA-EI300 scraper three roll transfer coating machine, roll to roll method, continuous and intermittent coating, width 300mm, coating width 50-260mm, coating surface density accuracy ± 1.5%, 150 ℃ hot air oven, suitable for 8-30 μ m thick metal substrates, including slurry stirring, winding correction function, optional NMP treatment and plasma cleaning.

Functional Features:

1. Wide coating window, suitable for various coating scenarios, especially suitable for the early research and development stage;

2. Can achieve continuous and intermittent coating;

3. Measurement with comma scraper, manual adjustment of scraper height, high coating accuracy;

4. Manually adjust the coating width;

5. The material box contains mixing function.

6.Substrate tension control, stable tape running, equipped with winding correction device;

7.Hot air oven, double-sided blowing on both sides, with high-quality drying effect;

8.PLC control, HMI operation, convenient and easy to use;

9.Optional additive treatment device.

Product Name | Roll to Roll Coating Machine |

Power Supply | Single phase AC220V ± 10%, frequency 50Hz, power 5KW |

Gas Source | 0.5-0.8MPa compressed air |

Coating Type | continuous coating, Intermittent coating |

Applicable Systems | positive electrode oil-based slurry (lithium cobalt oxide, lithium iron phosphate, lithium manganese oxide, ternary), negative electrode water-based slurry (graphite, silicon-based negative electrode), supercapacitor slurry |

Applicable Systems | Guide roller width 300mm |

Substrate Width | Max.280mm |

Coating Width | 50-250mm, adjustable through baffle |

Mechanical Speed | 0.01-0.7m/min |

Coating speed | Max.0.3m/min reference graphite negative electrode coating speed, viscosity 2000 mPa. s, solid content 45%, coating dry thickness 90um) |

Coated steel Rod | Ф100mm, Surface chrome plating, circular runout ≤ 3 μ m (measured by mechanical micrometer) |

Coating Roller | Ф100mm, Surface EPDM rubber |

Rubber Roller Movement | Cylinder driven |

Coating Scraper | Ф100mm, Surface chrome plated, single blade |

Scraper Adjustment | Manual adjustment, micrometer display accuracy of 1 μ m |

Coating Thickness | Continuous coating single-sided dry thickness: 30-150 μ m (depending on the slurry, refer to material requirements) |

Intermittent Coating single-sided Dry Thickness | 30-100 μ m (depending on the slurry, refer to material requirements) |

Accuracy | ≤ ± 3 μ m (reference, excluding edge abnormal areas, sampling and measurement standards refer to product evaluation) |

Align Both Sides | ± 0.5mm (length direction) |

Box Capacity | About 0.7L (coating width 160mm) |

Drying Unit | Single section length 0.8m, total 1 section (standard with hot air drying) |

Drying Temperature | Max 150 ℃, uniformity ± 5 ℃ (working position, except for the beginning and end), adjustable |

Air Intake | Centrifugal fan, air volume 198 m ^ 3 ⁄ h, power 50W |

Exhaust Air | Centrifugal fan, air volume 570 m ^ 3 ⁄ h, power 200W, interface: 5-inch Aluminum Foil duct |

Heating Box | U-shaped heating tube, total 4KW |

Tension Control | Max.60N |

Roll Diameter | Max.Ф250mm |

Retractable Core | 3-inch expansion shaft |

Operation Direction | Along the direction of foil transfer, the right side is the operating side |

Equipment Dimensions | L1650 * W950 * H1050mm |

Weight | 1000 kg |

Contact: Lika

Phone: +86-19906035385

Tel: 0086-592-7161550

Email: sales@aotbattery.com

Add: No.168, Zhaogang Road, Xiamen City, China