Home > News

1、Coater equipment principle and classification

The principle of the electrode coating equipment: the material required for the formula such as the positive or negative electrode is evenly mixed and coated or compounded on the front and back of the Aluminum Foilor copper foil, if you need to volatilize the solvent in the slurry by means of energy conduction to meet the customer's technical requirements of electromechanical integration equipment.

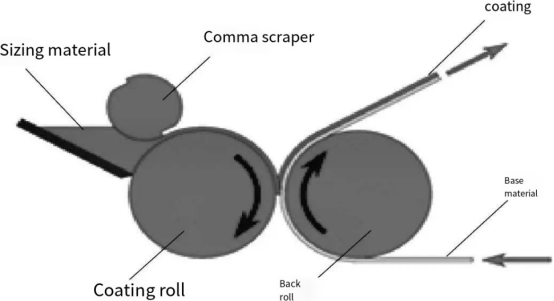

The comma scraper reverse transfer coating principle is shown in the figure.

2、Equipment composition and key structure

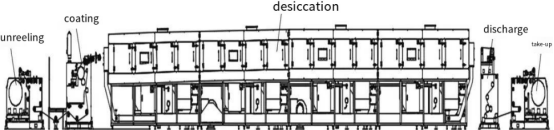

The equipment is composed of five parts: winding unit, coating unit (including feeding system), drying unit, discharging unit and winding unit. Coater unit composition is shown in the figure.

Unwinding Unit:

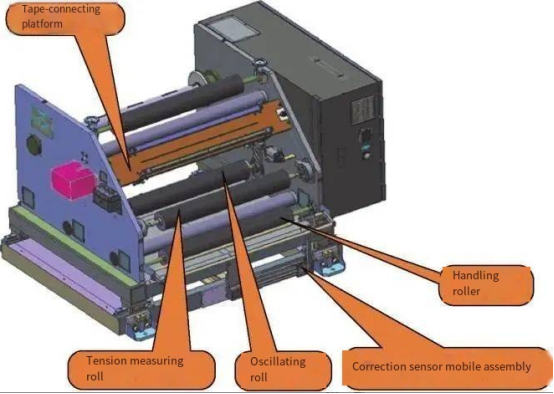

Reel release modes include automatic tape connection mode and manual tape connection mode. The unit for manual tape connection and reel release is shown in the figure.

The coil material to be produced is installed on the spool, and after correction and tension control, it is introduced into the coater part. The main control points of the device are unwinding correction and tension.

The correction is realized by a dedicated EPC control unit, and the ultrasonic position detection sensor (which can detect the transparent foil) detects the position of the material edge in real time, and moves left and right through the motor to drive the winding device, so that the relative position of the edge of the material and the correction sensor is constant.

The correction mode is divided into three types: automatic, the control system will enter the automatic correction state after power (according to the correction sensor to determine the movement of the drive motor); Semi-automatic: When the system is running automatically (coating, traction), it enters the automatic correction state, and when it is stopped, it enters the manual correction state; Manual, no matter what state the system is in, the correction mechanism can only be operated manually.

Tension control is divided into two parts: float roller position control and actual tension control. Float roller position control principle: When the system automatically runs, PLC controller according to the potentiometer feedback real-time float roller position signal (0%~100%), with PID algorithm to adjust the speed of the reel motor, in order to achieve a constant float roller position (default setting position is 50%).

The actual test tension control can be divided into three adjustment modes, that is, manually set the output proportion of the electro-pneumatic change valve, open loop set electro-pneumatic change valve, and closed loop set electro-pneumatic change valve. After the system runs automatically, the manual state is cleared and the automatic adjustment mode is switched. In the closed-loop setting mode, the control system will perform PID adjustment according to the measured tension value and the set tension value until the measured value is consistent with the set value. It should be noted that the closed-loop setting mode works only when the deviation between the actual position of the float roller and the set position is within ±20%.

3、Operation mode of coating machine

1. Confirm that the oven temperature is consistent with the process requirements, the tension and deviation correction are cut to the automatic position, and the lamination on the connecting plate is in the loosened state.

2, according to the automatic coating start the first interview film, test the film to confirm that there is no residual slurry on the roller; After coating 3 pieces, press the work stop key, and send the coating material into the oven to dry with the manual key of the back roller.

3, after the material is dry, reverse the sheet, take the third pole sheet, and take samples in the left (L), middle (M) and right (R) positions.

4. Confirm and check the thickness, width, length, amount of coating and adhesion of the first piece immediately. There should be no exposed foil, cracks, particles and uneven white space in the appearance. After passing the self-test, sample is sent to IPQC for the first piece confirmation according to QC requirements; If it is confirmed that it is not qualified, it will notify the process technician and the equipment debugging personnel to make adjustments until it is confirmed that it is qualified.

4、Role of coating machine

Lithium battery scraper coater is a kind of equipment used for coating film or coating, the paint is evenly coated on the surface of the substrate through the scraper, which is widely used in printing, painting, electronics and other fields. Its precise and uniform coating ability makes it an indispensable tool in the production process.

1. The scraper coating machine has the coating function of high precision and high uniformity. By adjusting the pressure, speed and Angle of the scraper, the precise control of the coating thickness can be achieved to ensure the uniformity and consistency of the coating film. Whether it is for coating on a flat substrate or for coating complex surfaces, the scraper coater can achieve precise coating effects to meet the needs of different products.

2. Lithium battery scraper coating machine has the characteristics of wide applicability. Different types of coatings, such as inks, glues, coatings, etc., can be effectively coated by a scraper coater. Moreover, the scraper coating machine is suitable for a variety of substrates, including paper, plastic, metal, etc., with strong applicability and flexibility.

3. The scraper coater also has a high degree of automation and intelligence. The modern scraper coater is equipped with advanced control system and automation device, which can realize automatic adjustment and optimization of coating parameters, improve production efficiency and coating quality. The equipment is simple to operate, only need to set the corresponding parameters, the machine can automatically complete the coating process, reducing the interference of human factors.

4. As a precise and uniform coating tool, lithium battery scraper coating machine has the characteristics of high-precision coating function, wide applicability, automation and intelligence, providing important support for the production of printing, painting, electronics and other industries. With the continuous development of industrial production and the continuous progress of technology, scraper coater will play an increasingly important role in the field of coating.

Contact: Lika

Phone: +86-19906035385

Tel: 0086-592-7161550

Email: sales@aotbattery.com

Add: No.168, Zhaogang Road, Xiamen City, China