Home > News

1、 the magical properties of graphene

2、 the application of graphene in the positive electrode material of lithium batteries

3、the application of graphene in the negative electrode material of lithium batteries

4、other applications of graphene in lithium batteries

5、Future prospects of graphene lithium batteries

With the rapid development of science and technology, energy storage technology has become the key to promote the progress of electric vehicles, portable electronic devices and other fields. Among many new materials, graphene, with its unique two-dimensional structure and excellent performance, has become a shining star in the field of lithium battery production

1、 the magical properties of graphene

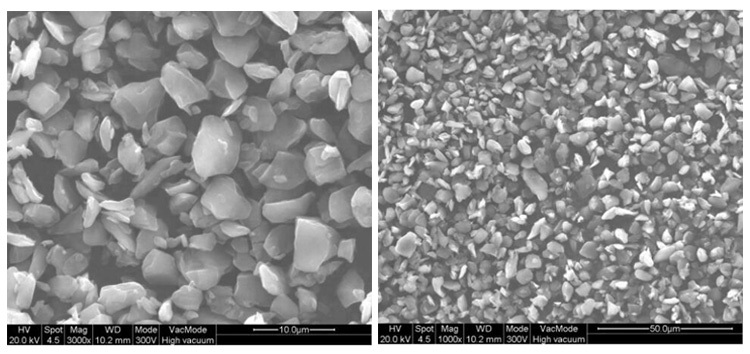

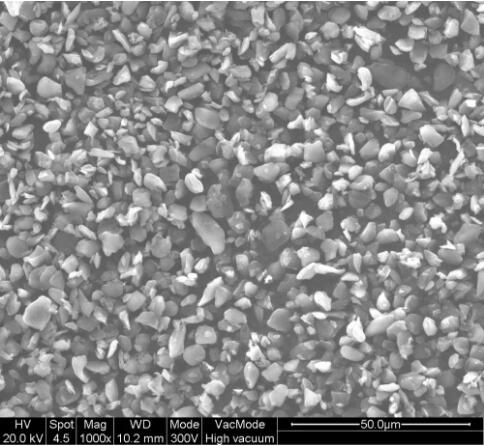

Graphene, a two-dimensional material composed of a single layer of carbon atoms arranged in a hexagonal honeycomb, has attracted wide attention from the scientific community since it was successfully stripped for the first time in 2004 for its excellent electrical and thermal conductivity, mechanical strength and high specific surface area. Graphene powder is currently known to be the least resistive material, electrons in which almost unhindered transport, which makes it in the energy, electronics, materials science and other fields to show great potential applications.

2、 the application of graphene in the positive electrode material of lithium batteries

In lithium batteries, the cathode material is one of the key factors determining the performance of the battery. Traditional cathode materials such as lithium iron phosphate (LiFePO4) have the advantages of good cycle performance and high theoretical specific capacity, but their poor conductivity limits the overall performance of the battery. The addition of graphene provides a solution to this problem. By combining LiFePO4 with graphene, the material's electrical conductivity can be significantly improved, thereby improving the battery's rate performance and cycle stability. The research shows that the introduction of graphene not only improves the conductivity of LiFePO4, but also promotes the rapid transfer of lithium ions, so that the battery can maintain a high specific capacity under high rate charging and discharging conditions.

3、the application of graphene in the negative electrode material of lithium batteries

Negative electrode materials are also an important part of lithium batteries. The ideal anode material should have the characteristics of low and stable REDOX potential, large reversible capacity, good cycle stability and low cost. Because of its high conductivity and good mechanical properties, graphene has become a hot spot in the research of negative electrode materials. When used directly as a negative electrode material, although graphene faces the problem of easy stacking leading to a decline in magnify performance, it can significantly improve the overall performance of the negative electrode material by combining with other materials, such as transition metal oxides and silicon-based materials. For example, the silicon/graphene composite material formed by the composite of graphene and silicon can effectively alleviate the volume expansion problem of silicon during the charge and discharge process, and improve the cycle life and energy density of the battery.

4、other applications of graphene in lithium batteries

In addition to being an electrode material, graphene can also be added to lithium batteries as a conductive additive to optimize the conductivity of the battery. Graphene's large surface area and excellent electrical conductivity enable it to build a large high-speed conductive network between electrode materials, improving the migration rate of lithium ions and electrons. In addition, the flexibility and mechanical strength of graphene also provide the possibility for the development of highly deformable lithium-ion batteries. For example, flexible batteries made by coating graphene films on a flexible substrate not only have excellent electrochemical performance, but also have good mechanical adaptability and portability.

5、Future prospects of graphene lithium batteries

Although the application of graphene in the production of lithium batteries has broad prospects, its high cost is still the main factor restricting its large-scale commercialization. With the continuous progress of preparation technology and the gradual reduction of production costs, graphene lithium batteries are expected to achieve a wider range of applications in the next few years. At the same time, in-depth research on the composite mechanism and interface stability of graphene and other materials will further promote the performance of graphene lithium batteries and the maturity of technology.

In short, graphene, as a revolutionary new material, has shown great potential and value in the field of lithium battery production. With the continuous deepening of research and continuous progress of technology, we have reason to believe that graphene lithium batteries will play a more important role in the future energy storage field and contribute to the sustainable development of human society.

Contact: Lika

Phone: +86-19906035385

Tel: 0086-592-7161550

Email: sales@aotbattery.com

Add: No.168, Zhaogang Road, Xiamen City, China