Home > News

一、Definition and classification of battery Aluminum Foil

二、the importance of battery aluminum foil in the lithium battery industry

三、the production process of battery aluminum foil

四、the impact of battery aluminum foil on battery performance

五、 the technical trend of battery aluminum foil

六、the market prospects of battery aluminum foil

七、the future development trend of battery aluminum foil

ith the rapid development of science and technology, lithium batteries, as an efficient and lightweight energy storage solution, have been widely used in electric vehicles, smart phones, laptops and other electronic products. In the manufacturing process of lithium batteries, battery aluminum foil as a core material, its quality and performance directly determine the overall performance and service life of the battery. In this paper, the definition, classification, production process, standard specifications and its importance in the lithium battery industry will be deeply discussed.

一、Definition and classification of battery aluminum foil

Battery aluminum foil, also known as battery grade aluminum foil, is a aluminum foil material specially used for the production of batteries. Compared with traditional aluminum foil, battery aluminum foil has higher purity and more stringent performance requirements. Battery aluminum foil is mainly used for the positive electrode collector of lithium-ion batteries, and its main function is to bring together the current generated by the active substance of the battery in order to form a larger current output. At the same time, aluminum foil, as an electrode collector, also needs to withstand the heat and charge generated by the battery, and transfer the charge from the electrolyte to the electrode surface through conductive properties.

According to the use of different occasions, battery aluminum foil can be divided into polymer lithium ion battery aluminum foil and lithium cobalt acid battery aluminum foil two. Polymer lithium ion battery aluminum foil is usually double-sided oxidation treatment, the surface is coated with a special polymer, and special corrosion resistance treatment to adapt to the special working environment of polymer lithium batteries. Aluminum foil for lithium cobalt acid batteries is usually one-sided oxidation treatment, and the surface can be coated with a special organic coating to improve its corrosion resistance and electrical conductivity.

二、the importance of battery aluminum foil in the lithium battery industry

(1)Current collection and transmission: As a positive collector fluid, the battery aluminum foil has excellent electrical conductivity, which can efficiently collect the current generated by the active substance of the battery, and connect with the external circuit through the pole to achieve the transmission of electrical energy. This function is essential to ensure the high-performance output of lithium batteries.

(2)Thermal stability: The aluminum foil can withstand the heat generated by the battery during the charging and discharging process, ensuring the stability and safety of the battery under extreme working conditions. This is particularly important for applications such as electric vehicles that require long, high-load operations.

(3)Cost effective: Compared to other metal fluid collecting materials, aluminum foil has a high cost performance. Its rich resources and mature processing technology make aluminum foil the preferred material for fluid collection of lithium batteries.

三、the production process of battery aluminum foil

The production process of battery aluminum foil is relatively complex and needs to go through multiple links of treatment and processing. The following are the basic steps for the production of battery aluminum foil:

(1) Raw material preparation: Select high-purity aluminum alloy as the main material, after melting, refining and other treatment, remove impurities and gases, to ensure the purity of raw materials.

(2) Casting: the molten liquid aluminum is poured into the aluminum roll body, and the aluminum billet is formed after cooling by the continuous casting unit. This step requires strict control of the size and shape of the aluminum billet to ensure the smooth progress of subsequent processing.

(3) Rolling: Put the aluminum billet into the rolling mill for continuous rolling, rolling it into a relatively thin aluminum sheet. Rolling pressure and speed need to be adjusted during the rolling process to obtain the ideal thickness and surface quality of aluminum sheet.

(4) Annealing: the rolled aluminum sheet is annealed to eliminate the internal stress and improve the ductility and toughness of the aluminum sheet. Annealing temperature and time need to be adjusted according to the specific material and process requirements.

(5) Pre-shear: pre-shear the annealed aluminum sheet to make it the right size for subsequent processing.

(6)Surface treatment: The pre-cut aluminum sheet is subjected to a certain surface treatment, such as pickling, alkali washing, etc., to remove impurities such as oxide and oil on the surface, and improve the smoothness and finish of the surface.

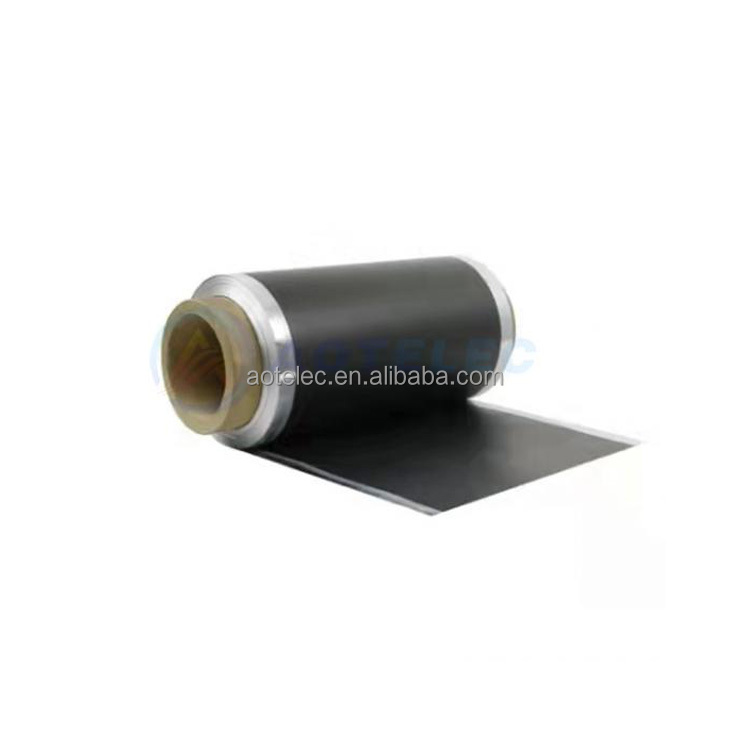

(7) Coating: the surface treated aluminum sheet is coated to increase the electrical conductivity and corrosion resistance of the battery aluminum foil. The selection of coating materials and the coating process need to be optimized according to the specific use environment and requirements.

(8) Re-cutting: the coated aluminum sheet is re-cut to make its size and shape more accurate and meet the manufacturing requirements of lithium batteries.

四、the impact of battery aluminum foil on battery performance

The quality and performance of the battery aluminum foil directly affect the performance and stability of the battery. First of all, high-quality aluminum foil has good electrical conductivity, can effectively transmit current, reduce the internal resistance of the battery, and improve the charge and discharge efficiency of the battery. Secondly, aluminum foil also needs to have high mechanical strength and good corrosion resistance to ensure that the battery can operate stably in a variety of working environments. In addition, parameters such as the thickness, surface finish and flatness of the aluminum foil also affect the performance and life of the battery. Therefore, in the battery production process, it is crucial to choose the right aluminum foil material and manufacturing process.

五、 the technical trend of battery aluminum foil

(1) High purity, high performance: With the improvement of lithium battery energy density and safety requirements, the purity and performance requirements of battery aluminum foil are becoming higher and higher. In the future, battery aluminum foil will develop in the direction of higher purity, higher strength and lower impedance.

(2) Environmental protection and sustainability: Under the global trend of environmental protection and sustainable development, the production of battery aluminum foil will also pay more attention to environmental protection and sustainability. For example, the use of green production technology, improve the recycling rate of resources, etc.

(3) The development of a new aluminum foil anode: the use of aluminum foil to manufacture batteries with higher energy density and higher stability. This technical trend provides a new direction for the development of battery aluminum foil.

六、the market prospects of battery aluminum foil

(1) Market demand growth: With the popularity of electronic products such as electric vehicles and smartphones, as well as the development of new application fields such as energy storage power stations, the demand for lithium batteries will continue to grow, thereby driving the expansion of the battery aluminum foil market.

(2) Technological progress to promote industrial upgrading: With the continuous progress of battery aluminum foil technology, its application field will continue to expand. For example, the research and development of new battery technologies such as solid-state batteries will bring new growth points to the battery aluminum foil market.

(3) International competition and cooperation: In the context of global integration, the battery aluminum foil market will show an international trend. Domestic enterprises will strengthen cooperation with international large battery manufacturing enterprises, increase product exports, and expand overseas markets.

七、the future development trend of battery aluminum foil

With the continuous development and application of new energy technologies, the requirements for battery performance and safety are also increasing. In the future, with the rapid development of electric vehicles and other fields, higher requirements are put forward for the energy density, cycle life and safety of batteries, so the research and development and production technology of battery aluminum foil will also be further breakthroughs and improvements. In addition, with the development of renewable energy and energy storage technology, the application of battery aluminum foil in energy storage systems will also gradually increase, providing cleaner and sustainable energy solutions for mankind.

八、Conclusion

As an important part of the battery, the battery aluminum foil plays a vital role in the battery production. Through the introduction of this article, we can have a more in-depth understanding of the role of battery aluminum foil, manufacturing process and the impact on battery performance. It is believed that with the continuous progress of science and technology, battery aluminum foil will play an increasingly important role in the future, creating more efficient, safe and environmentally friendly energy solutions for mankind.

Contact: Lika

Phone: +86-19906035385

Tel: 0086-592-7161550

Email: sales@aotbattery.com

Add: No.168, Zhaogang Road, Xiamen City, China